Abrasion-resistant polyurethane cables are used in rail systems and are resistant to tensile, torsional and high mechanical stresses. They contain a bundle of optical fibres for data transmission and are suitable for mobile equipment such as mobile cranes, lifting equipment and heavy excavators.

Abrasion Resistant Polyurethane Cable Product Features:

Resistant to bending, abrasion, oil, UV (no cracking), tensile (with steel wire and high-strength cotton rope), produced using German VDE standards.

Service life: 4~5 times the service life of rubber cable.

Suitable for towing system

The cable can move at a speed of up to 240m/min.

Tension load is 15N/mm2

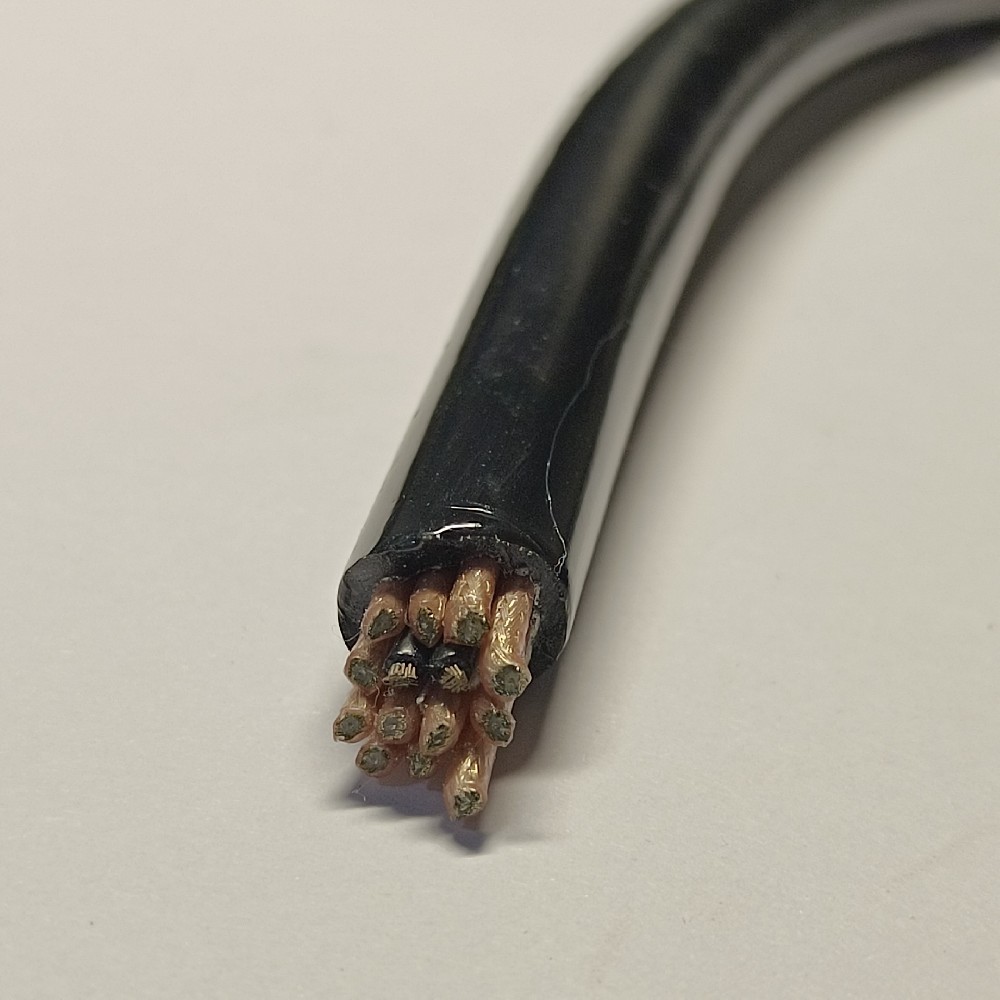

Abrasion-resistant polyurethane cable structure

Conductor material: fine bare copper multi-stranded with high bending strength (in accordance with IEC60228 cl.5/VDE0295 cl.5)

Core insulation: polyurethane

Core identification: up to 5 cores according to VDE 0293 coloured cores, from 6 cores upwards black cores white numerical numbering with green-yellow earth wire or DIN 47100)

Sheath colour: black

Stranding: Multi-layer stranding

Tensile material: Central textile reinforcing core

Characteristics of abrasion-resistant polyurethane cables:

First, wear-resistant performance: when the cable is often subject to friction, scraping and grinding, research and frustration and other mechanical effects in the process of use, will cause its surface, and gradually wear, so the choice of material abrasion is very important. TPU plastic raw materials excellent abrasion resistance, wear-resistant more than five times more than the natural rubber (rubber cables) is one of the preferred materials for abrasion-resistant products.

Second, tensile performance: polyurethane cable tensile strength of up to 38MPa, ordinary rubber cable (one of the most common cables on the market) tensile strength of only 8-12MPa. When the cable is used in the environment with forced traction, rubber cable sheath tensile effect is poor, the wire core by the external tension is very easy to break the core after the situation. Polyurethane cable sheath and insulation of excellent tensile properties of the core to play a good protective role, making it durable.

Third, the tearing performance: polyurethane cable in the application due to produce cracks to expand and make the damage is called tearing, tear strength is the ability of the material to resist the role of tearing; generally speaking, TPU has a high tear resistance, tear strength and some commonly used rubber and plastic comparisons is very excellent.